©2025 Pacific Gas and Electric Company

Your new pge.com account is almost here! We’re adding easier password resets, improved security and more. Make sure we have your current phone number and email address so you don’t get locked out. Don't get locked out!

Error: Field cannot left blank.

Error: Invalid entry. Do not use equal signs [=] or colons [:].

Error: Field cannot left blank.

Error: Invalid entry. Do not use equal signs [=] or colons [:].

Pipeline inspection

PG&E is committed to the safety of the communities it serves and is working to enhance pipeline safety throughout northern and central California. Key to this effort is the inspection of PG&E's nearly 7,000 miles of gas transmission pipelines and 42,000 miles of distribution pipelines. By regularly monitoring and inspecting these networks of gas pipelines, PG&E is able to identify and address concerns before they become a problem.

PG&E is a partner in developing and deploying new technologies that are helping transform utilities into more predictive and proactive operators and helping aid in providing detailed inspections—often in less time and with greater accuracy and precision than traditional methods.

3D Toolbox

PG&E is working with a new technology that looks for warning signs, such as dents, cracks or corrosion, on the outside of gas pipelines. 3D Toolbox is as easy to use as a digital camera, and with a click, it captures an image and provides measurements—giving PG&E real-time information about the condition of pipeline surfaces. This technology allows pipeline engineers and corrosion experts to view images on a laptop at the dig site, assess any surface defects or issues within minutes and put together a corrective plan immediately. In addition, a major advantage of the system is that it provides a traceable digital record of the measurements, allowing engineers to easily store and access the data in the future.

EXAscan

PG&E also utilizes a portable, handheld 3D laser scanner called the EXAscan. The EXAscan is able to replace time consuming manual tasks and provide a much more detailed evaluation of a pipeline than was previously available. It can measure, for example, the extent of external corrosion or characterize any warping.

A trained engineer or technician simply holds the scanner a few inches above a section of pipeline. The device transmits data to a computer program, which creates a 3D model of the object and displays it on a monitor. The software includes color coding to show where pipeline damage is most severe, along with many other measurements. The data is accurate within 40 microns, or 0.0016 of an inch.

Hydrostatic testing

Hydrostatic testing involves pressurizing a pipe with water to reveal potential weaknesses and is a proven method for verifying the capability of a natural gas pipeline to operate at a safe level of pressure. Hydrostatic testing is also used to test such familiar items as scuba tanks, fire extinguishers and air compressor tanks.

Hydrostatic pressure testing. entails filling a pipe with water, pressurizing it to a much higher level than the pipe will ever operate with natural gas and then monitoring the pipe for approximately eight hours. Since 2011, PG&E has pressure tested more than 673 miles of natural gas transmission pipelines throughout its service area.

Pipeline replacement

PG&E operates the second largest gas transmission and distribution system in the country and has made significant progress in accelerating leak repair and prevention across its 80,000-mile natural gas system.

By the end of 2014, PG&E replaced 2,270 miles of its cast iron and pre-1940 steel distribution main—which can be prone to leaks—with modern, new materials. This means PG&E is one of the first utilities of comparable size and age to complete such an action.

Safety initiatives

Pipeline safety

PG&E is committed to building the safest and most reliable gas system in the nation, so that we can continue to provide the energy that our customers will depend on for many decades to come.

Safer pipelines across our state

PG&E has numerous pipeline safety programs, policies and procedures in place to ensure the safety of our customers, employees and the public.

- Pipeline access: Maintaining the area above our pipelines and ensuring crews have ready access is a key part of our ability to safely operate the system.

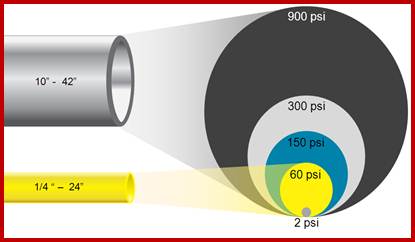

- Regional pipelines: Larger-diameter transmission pipelines carry natural gas across our state.

- Neighborhood pipelines: Smaller-diameter distribution pipelines serve local homes and businesses.

- Maintenance and monitoring: No matter the size, we monitor our system status in real time on a 24-hour basis, and through regular surveys and patrols.

My pipeline

PG&E has a comprehensive inspection and monitoring program to ensure the safety of its natural gas transmission pipeline system.

Gas safety plan

Learn about safety measures we are taking to make you safer.

Download 2025 gas safety plan (PDF)

Download 2024 gas safety plan (PDF)

Download 2023 gas safety plan (PDF)

Download 2022 gas safety plan (PDF)

Download 2021 gas safety plan (PDF)

Download 2020 gas safety plan (PDF)

Download 2019 gas safety plan (PDF)

Download 2018 gas safety plan (PDF)

Download 2018 leak abatement compliance plan (PDF)

Download 2018 gas safety plan attachments (ZIP)

Download 2017 gas safety plan (PDF)

Additional resources

Pipeline

Read more about pipeline inspection, replacement, and safety initiatives

Gas Tools

PG&E is committed to the safety of the communities it serves and is working every day to enhance gas pipeline safety.

©2025 Pacific Gas and Electric Company