Your new pge.com account is almost here! We’re adding easier password resets, improved security and more. Make sure we have your current phone number and email address so you don’t get locked out. Don't get locked out!

Error: Field cannot left blank.

Error: Invalid entry. Do not use equal signs [=] or colons [:].

Error: Field cannot left blank.

Error: Invalid entry. Do not use equal signs [=] or colons [:].

Why hydrogen?

We believe hydrogen will play a critical role in California’s decarbonized future. In addition to decarbonizing the gas system, using zero-carbon fuels like hydrogen can help reduce the carbon footprint in hard-to-electrify areas.

Hydrogen is relevant to PG&E as a fuel, as a feedstock for renewable natural gas (RNG), or as a carbon-free energy carrier when blended with natural gas. We will leverage our integrated natural gas and electric businesses to explore applications for hydrogen such as fuel cell electric vehicles (FCEV), fuel for electric microgrids, and combustion in existing power plants and appliances. Hydrogen is one of the ways PG&E is aiming for a net-zero carbon energy system in 2040—five years ahead of California’s carbon-neutrality goal.

The Hydrogen to Infinity project

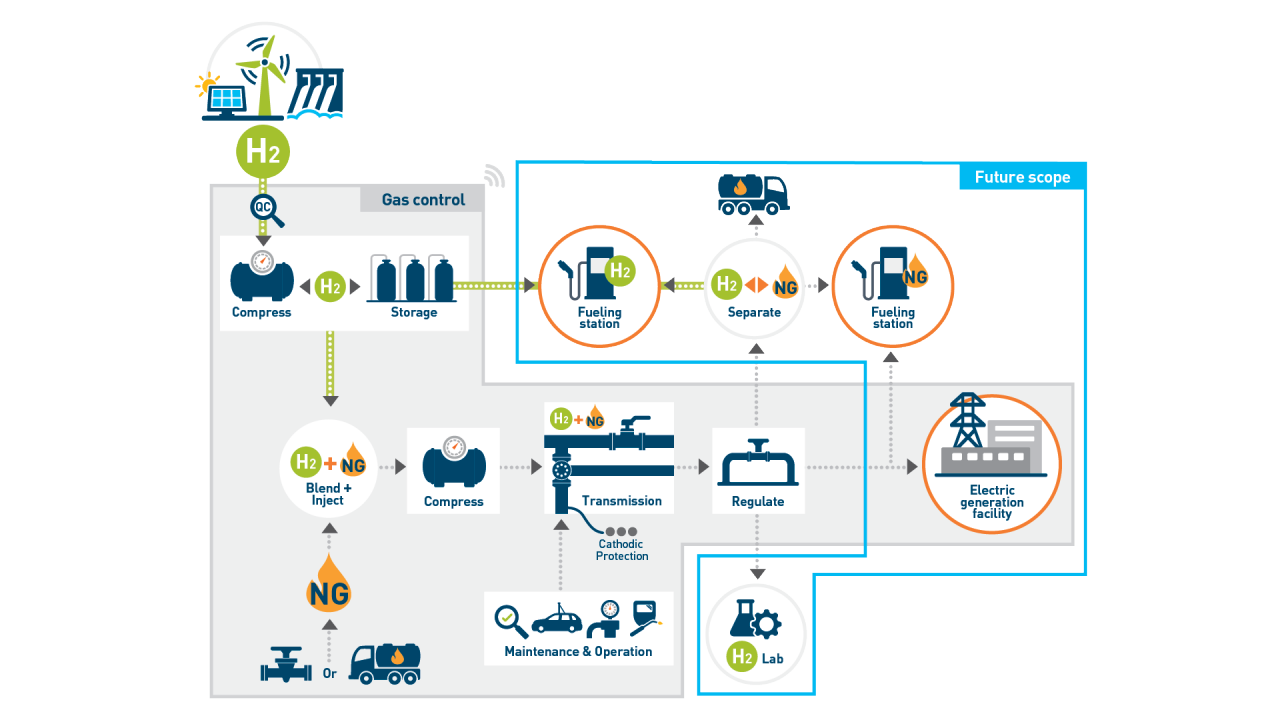

PG&E and our collaborators have launched the nation’s most comprehensive end-to-end hydrogen gas transmission facility, called Hydrogen to Infinity or H2∞. It will blend hydrogen and natural gas in an isolated transmission pipeline and storage system. The 130-acre facility will be built in Lodi, California and serve as an operational proving ground for hydrogen production pathways, pipeline transportation, storage, and ultimately, combustion at the Lodi Energy Center power plant.

H2∞ will use clean hydrogen powered with on-site renewable energy, supplemented by the local electric grid that includes significant renewable power. The water source for the hydrogen production is the City of Lodi’s White Slough Water Treatment facility. It can provide reclaimed water with zero impact to the local water supply.

Green hydrogen has several potential applications, including fuel for the transportation market, especially in heavy-duty vehicles, marine and rail. Hydrogen is also well suited for use as seasonal energy storage, and hydrogen-natural gas blends are being considered for direct use in existing gas appliances.

PG&E supports the demonstrations by the other California pipeline operators that focus on distribution pressure projects and end uses. Together with our project, all aspects of hydrogen blending into existing natural gas infrastructure are covered to prepare for a state-wide hydrogen injection standard.

Hydrogen to Infinity overview

Our goal is to make the hydrogen project operational by the end of 2027, with potential future phases in the years after.

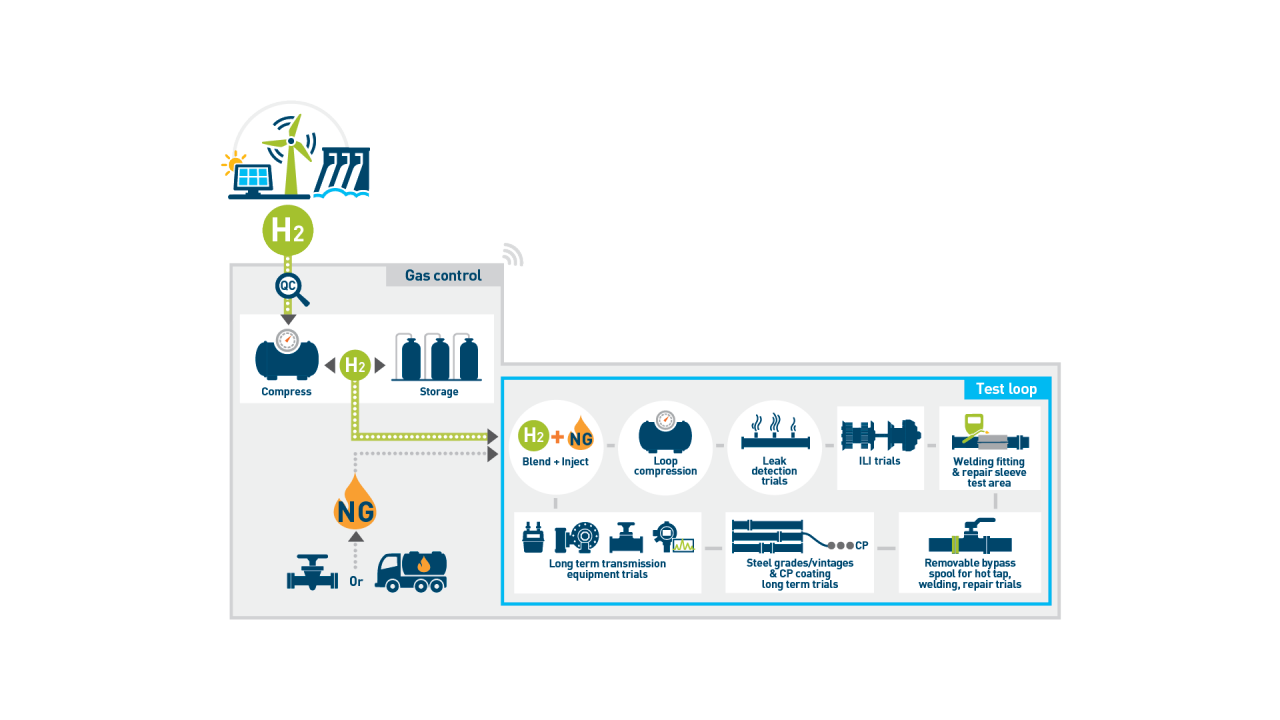

H2∞ will study different levels of hydrogen and natural gas blends in a stand-alone multi-feed, multi-directional and closed natural gas transmission pipeline system (test loop). This will include testing different vintage gas pipes and inform a safe level of hydrogen we can blend into the existing system by 2030. The facility is planned to operate for a minimum of 10 years and extend indefinitely as an active asset.

Future scope

Future phases of the project may include the following:

- A full-scale offline testing facility to enable testing of full-scale equipment compatibility, leak testing, and full-scale materials and integrity testing. This facility could fill gaps recognized by the gas industry in scaling up laboratory research.

- A laboratory to include testing laboratories and workshops. It will enable laboratory-scale testing to support research and testing programs ahead of full scale and live testing programs. It can also support investigations and inspection of equipment and samples before, during, and after the full-scale testing.

- An education and training facility to include dedicated classrooms and additional training areas for knowledge dissemination and safety/operations training for the utility workforce.

- A de-blending area testing de-blending technologies to separate the hydrogen-natural gas blend and demonstrate achievable purities for vendor technologies and sensitive customer equipment. This would feed a pure hydrogen supply into a Hydrogen Fueling Station (with on-site compressed storage) which could cater to heavy duty, light duty, and bus fleet vehicles.

- An interconnection pipeline to provide hydrogen natural gas blends to the Lodi Energy Center power plant for combustion to produce electricity.

- Evaluating new and existing pipeline assets in a controlled natural gas and hydrogen blend environment.

- Testing the majority of transmission assets and creating a lasting research and innovation space.

- Developing expertise and training personnel in operations, maintenance and safety through hands-on operational experience with a hydrogen blended system.

- Fostering innovation and advancements toward the future of gas pipelines and energy supply systems.

- Reaching climate goals by showcasing the ability to displace fossil natural gas with low-carbon hydrogen in the natural gas system, positively impacting climate change.

- Educating and informing community leaders, customers and the public about using hydrogen as a carbon-free fuel and its role in helping decarbonize energy systems.

Visit Northern California Power Agency

If you would like to discuss potential future hydrogen collaborations with PG&E, please email Hydrogen@pge.com.

Additional hydrogen efforts

California Hydrogen Hub

A complementary initiative to PG&E’s Hydrogen to Infinity Project is the California Hydrogen Hub.

As announced On October 13, 2023, the United States Department of Energy (DOE) awarded California up to $1.2 billion from to build and expand projects focused on clean energy and creating green jobs. The goal is to achieve a net-zero carbon economy by 2045.

California is one of seven awardees of the DOE’s Regional Clean Hydrogen Hubs (H2Hubs). The H2Hubs form a national network of clean hydrogen producers, consumers, and connective infrastructure. They support the production, storage, delivery and end-use of clean hydrogen. Together, they are expected to:

- produce three million metric tons of hydrogen annually

- reach nearly a third of the 2030 U.S. hydrogen production target

- lower emissions from hard-to-decarbonize industrial sectors that represent 30 percent of total U.S. carbon emissions

- reduce 25 million metric tons of carbon dioxide (CO2) emissions from end-uses each year — an amount roughly equivalent to the annual emissions of 5.5 million gas-powered cars

- create and retain tens of thousands of good-paying jobs across the country

- support healthier communities

Research and development

PG&E has been actively involved in R&D around hydrogen production, hydrogen blending in the natural gas system and hydrogen utilization since 2018. A hydrogen roadmap was developed and guides key R&D activities to move the company towards achieving a carbon neutral and renewable gas system.

- Production

Priorities for hydrogen production R&D work includes steam methane reforming with carbon capture, methane pyrolysis and using biomass as a starting feedstock. - Blending

Priorities for hydrogen blending in the natural gas system include understanding the impacts to integrity management, network capacity, underground storage, end use equipment, and leak mitigation and management. - Utilization

Priorities for hydrogen utilization include modifying existing natural gas customer equipment to run on a blend of natural gas and hydrogen and developing zero NOx emission hydrogen combustion processes.

Please refer to the R&D Strategy Report (PDF) for more information.

Frequently asked questions

Hydrogen is the most abundant element in the universe with atomic number 1 on the periodic table and is the simplest and lightest of the elements. Hydrogen gas, having two atoms (H2), is colorless, odorless, non-toxic and highly flammable.

Hydrogen doesn’t exist in large quantities in pure form on earth. It is always combined with other elements like carbon and oxygen. Examples include methane (CH4) and water (H2O). To isolate pure hydrogen, it must be separated from those other elements. This is done through two main methods: electrolysis and thermal conversion.

Electrolysis is the separation of water into hydrogen and oxygen and requires electricity. If the power source is renewable electricity the process is completely carbon free.

The most common thermal conversion method is a process called steam methane reforming (SMR). SMR is a reaction of methane and water to produce hydrogen and carbon monoxide. Other thermal conversion hydrogen production methods include methane pyrolysis and biomass gasification. Each can be lower in atmospheric carbon emissions than SMR.

Clean hydrogen is hydrogen made in a way that contributes little or no CO2 emissions to the atmosphere. This can be done with electrolysis powered by renewable energy or by thermal conversion of renewable natural gas, SMR with carbon capture or gasification of biomass also with carbon capture.

The PG&E system has pipelines, regulators and valves of varying types that were installed over time. Testing the vintage equipment ensures that we understand how those assets will operate over a long period of time with a blend of hydrogen and natural gas.

A Hydrogen Blending Impacts Study (PDF) was completed by the University of California, Riverside in July, 2022. You can reference this study on the California Public Utilities Commission website.

Related documents

More on hydrogen

2024 Corporate Sustainability Report

Read about PG&E's investment and innovation in energy.

PG&E biomethane page

Learn how PG&E supports your biomethane interconnection projects.

©2025 Pacific Gas and Electric Company

©2025 Pacific Gas and Electric Company