Your new pge.com account is almost here! We’re adding easier password resets, improved security and more. Make sure we have your current phone number and email address so you don’t get locked out. Don't get locked out!

Error: Field cannot left blank.

Error: Invalid entry. Do not use equal signs [=] or colons [:].

Error: Field cannot left blank.

Error: Invalid entry. Do not use equal signs [=] or colons [:].

If you smell natural gas or suspect an emergency, leave the area now and call 9-1-1.

If you see downed powerlines, stay away. Don’t exit your car or home. Call 9-1-1. Then call PG&E at 1-800-743-5000.

24-hour Customer Service Line: 1-877-660-6789

24-hour Power Outage Information Line: 1-800-PGE-5002 (1-800-743-5002)

- Gas safety tips

- Safety initiatives

- Gas meter safety inspections

- Safety requirements for contractors

Gas safety tips

Safety is our highest priority. Follow these safety tips to keep yourself and your family safe.

- Never use a flashlight, match or candle to look for gas leaks, and never turn electric switches on or off if you suspect a gas leak.

- Do not store flammable materials such as mops, brooms, laundry and newspapers near your water heater, furnace, oven, range or any gas appliance.

- Do not store combustible materials such as paints, solvents and gasoline in the same room as your water heater, furnace, oven, range or any gas appliance.

- Stock your kitchen with a fire extinguisher.

- If a pilot light is out, shut off the gas at the appliance gas shutoff valve. Wait five minutes to let gas disperse before trying to relight the appliance pilot light.

- Keep an adjustable pipe or crescent wrench or other similar tool near your main shutoff valve so you don’t have to search for one in times of emergency.

You can safely turn off the gas during an emergency by following a few simple guidelines.

Locate and shut off gas service

To stop the flow of gas into a building during an emergency, turn your gas off at the service shut-off valve.

PG&E installs gas service shut-off valves at all gas meter locations.

Follow these steps:

- Locate the main gas shutoff valve.

Your main gas shutoff valve is normally located near your gas meter. The most common places are on the side or front of a building, a cabinet located inside a building or a cabinet meter outside a building. - Have a wrench handy.

Keep a 12- to 15-inch adjustable pipe or crescent-type wrench or other suitable tool near your main shutoff valve so you don’t have to search for one in times of emergency. - Give the valve a quarter turn.

The valve is closed when the tang (the part of the valve you put the wrench on) is crosswise (perpendicular) to the pipe.

If your gas service is set up differently from the one described and you wish to know how to turn off your gas, please contact us.

Regulate your automatic shut-off device

Some city and county regulations require the installation of automatic gas shut-off devices. This installation may include excess flow gas shut-off valves and/or earthquake-actuated gas shut-off valves. The regulations can vary, but generally apply to new building construction, significant alterations and additions to existing buildings.

Check with your local city or county agency to see if regulations apply in your area.

- PG&E crews will need to gain access to properties. Every gas meter must be inspected and gas crews must ensure that no gas is flowing on the customer's property. Turning gas off at every meter is a necessary first step.

- Following that process, all active gas lines must be cleared of residual gas.

- Once gas has been cleared and it is safe to do so, gas service will be returned to the lines.

- After that, Gas Service Representatives will visit customer homes and businesses to restore service and relight pilot lights.

- The restoration of gas service requires several safety steps and crews work to restore service safely and quickly.

- As reminder, PG&E employees always carry their identification and are always willing to show it to you. Customers should always ask to see valid identification before allowing anyone claiming to be a PG&E representative inside their home. If a person claiming to be a PG&E employee has identification and you still feel uncomfortable, please contact us to verify PG&E's presence in the community.

It is important to know which appliances in your home run on gas. The most common gas appliances are stove top ranges, ovens, water heaters and furnaces.

Pilot lights

- Many older gas appliances and most water heaters have a small, continuously burning gas flame—the pilot light—that ignites the main burner. Some newer models have electronic igniters.

- If the pilot light is out, shut the gas off at the appliance’s gas shutoff valve. Always wait five minutes to let gas disperse before trying to relight an appliance pilot light.

- Follow the appliance manufacturer's instructions to relight a pilot light. Often, basic relight instructions are located inside the main burner compartment door. If you cannot relight the pilot light yourself, call PG&E or another qualified professional for assistance.

Gas appliance shutoff valves

- The State of California requires approval for all excess flow gas shut-off valves and earthquake-actuated gas shut-off valves used within the state. A list of approved valves is available. Visit DSA Gas Shut-off Valves Certification Program.

- If a customer installs an excess flow gas shut-off valve or earthquake-actuated gas shut-off valve, the valve must be certified by the State of California. A licensed plumbing contractor must install it according to the manufacturer’s instructions. We do not install or service seismic-actuated or excess flow gas shut-off valves. We do not recommend specific contractors for installation.

- Excess flow gas shut-off valves and earthquake-actuated gas shut-off valves must be installed on the building’s gas houseline piping. This pipeline is the gas pipe that connects your appliances to the gas meter downstream of the utility point of delivery. It is located after the PG&E gas shut-off valve, pressure regulator, meter and the service tee. No attachments or connections of any kind are allowed on the utility facilities before the point where the service tee connects to the gas houseline piping. After installation, the valve must not obstruct any gas operations or PG&E services in or around piping, gas service shut-off valves, gas meters and gas pressure regulating equipment.

- Most gas appliances have a gas shutoff valve located near the appliance that lets you turn off the gas to that appliance only. In some cases, turning off the gas at the appliance's shutoff valve will suffice if there is a gas leak or the appliance needs to be replaced or serviced. You should have an appliance gas shutoff valve installed at each gas appliance so that you can turn off the gas to that appliance only, instead of shutting off all gas at the main gas service shutoff valve.

Stoves (ranges and ovens)

- When lighting the burners, light the match before you turn on the gas. If the flame goes out, turn off the burner and let the gas disperse before relighting.

- Clean away any grease, oil or debris from the area to prevent a grease fire. In the event of a grease fire, never add water. Use baking soda or, if the fire is in a pan, use a lid to smother the flame. Stock your kitchen with a fire extinguisher.

- Move any flammable objects such as towels and curtains away from the burners.

- Never use your oven to heat your home. This misuse puts you at risk of burns from hot surfaces and shortens the life of oven parts and controls.

Water heaters

- Make sure your water heater is securely anchored to a wall to prevent it from shifting or falling during an earthquake.

- If your water heater is elevated, make sure the platform is sturdy enough to withstand the weight of the water heater if it moves during an earthquake.

Furnaces

- Have your furnace serviced once a year.

- Clean or replace your filter regularly—depending on how frequently you use it.

- Air supply vents must be clear of obstructions. Furnaces need a constant supply of fresh air to run efficiently and safely.

Recognize signs of a natural gas leak

Please report any signs of a gas leak immediately. Your awareness and action can improve the safety of your home and community.

- Alert everyone nearby and leave the area immediately to an upwind location.

- Do not use anything that could be a source of ignition, including cell phones, flashlights, light switches, matches or vehicles, until you are a safe distance away.

- Call 9-1-1 for emergency assistance and then call PG&E at 1-800-743-5000.

Safety initiatives

PG&E is committed to the safety of the communities it serves and is working every day to enhance gas pipeline safety throughout northern and central California.

Gas transmission vegetation safety

Keeping the area near pipelines clear and safe to allow for emergency access and prevent damage to the pipe.

Pipeline inspection

PG&E uses cutting-edge technology to inspect its nearly 7,000 miles of gas transmission and 42,000 miles of gas distribution pipelines.

Automated safety valve upgrades

Valve automation improves PG&E's ability to quickly shut off the flow of gas in the event of a significant change in pressure.

Pipeline replacement

PG&E has replaced 2,270 miles of its cast iron and steel gas distribution pipe, leading to fewer leaks—good for safety and the environment.

Leak-surveying

PG&E regularly surveys its 70,000-square mile service area by foot, vehicle, air and even by boat.

High-tech gas tools

Building on its efforts to enhance pipeline safety, PG&E has been an industry leader in supporting new technology.

Gas meter safety inspections

What is a gas meter inspection?

The safety of our customers and the communities we serve is our most important responsibility. Gas meter inspections are one of our essential safety programs.

Safety inspections include a visual examination of the meter. Our safety technicians will also conduct a test to identify if any leaks may be present. They are looking for any conditions which may require the meter set to be updated or repaired.

PG&E representatives will be in safety gear and will always carry photo identification, which they will be happy to present upon request. Typically, meter inspections do not cause interruption to your gas service unless a hazard is found.

Meter accessibility

The California Public Utilities Commission (CPUC) requires us to perform these important safety inspections. A qualified PG&E representative needs physical access to your gas meter to perform this mandated work. This safety inspection work may require our employees or contractors to enter your property as we access your gas meter, which is sometimes located in the garage or behind a gate.

By providing clear and safe access to the gas meters, customers are helping keep their gas facilities safe.

View images to determine your meter type

What to do if you received a notification that you're due for a meter inspection

We will reach out to you to schedule your gas meter inspection. You do not need to proactively call to schedule one. If you received a notification from us that you are due for an inspection you may schedule an appointment through our secure online customer portal, email accessmymeter@pge.com.

Confirm that your contact information is correct

Help us reach you when it's important by making sure that your email, phone number, language preference, and mailing address are current in your PG&E online account.

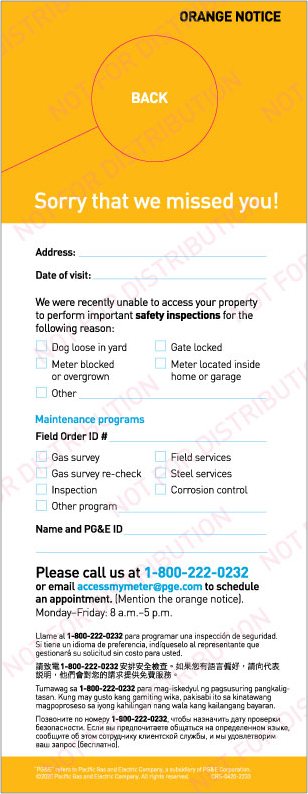

Examples of the communication you may receive from PG&E

Front:

Back:

Front:

Back:

Front:

Back:

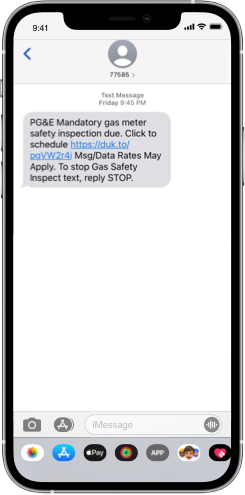

Text message example:

Frequently asked questions

A gas-meter safety inspection is mandated by the CPUC to occur every 1-3 years. To complete the required inspection, we need unobstructed access to the gas meter at your premise.

If you are not home or deny access to our technician, we will leave a doorhanger or contact you later.

We need unobstructed physical access to touch the entire meter. If there is nothing obstructing the meter, such as a locked gate or dogs, you do not need to be present.

A PG&E employee or contractor will visually inspect your gas meter and meter components to verify and identify possible areas of corrosion or rust. They may also use a small, handheld device for additional inspections or a mobile tablet to take photos of the meter ID, piping and entire meter set. The appointment typically takes 10-15 minutes.

The communications customers receive are requested 2-7 business days in advance, depending on what type of communication is being sent (phone call, postcard or letter).

Due to this lag time, you may receive a communication after your meter inspection is already completed. If that is the case, you will soon drop off the communications list. We apologize for any inconvenience or confusion this may cause.

To confirm completion of the correct inspection, reach out to the CGI team at AccessMyMeter@pge.com or 1-800-222-0232. Phone hours: Monday-Friday, 8 a.m. – 5 p.m.

We are required by CPUC mandate to inspect your gas meter. Also, we want to stress that an inspection helps ensure our equipment is safe and not in need of any repair.

If we find that the PG&E gas meter needs replacement or repair, it will be done at PG&E's expense.

Lastly, if we are unable to complete this required inspection, there is potential for you to lose gas or electric service.

Keys are held by our Meter Reading Department. We use contractors to assist with these safety inspections. We do not share keys with contractors or between PG&E departments.

Gas operations safety requirements for construction contractors

Access PG&E's current safety guidelines

Safety is the top priority at any PG&E construction job site. All Construction Contractor Managers and Work Crews working at a PG&E job site must read, understand and comply with the Gas Operations (GASOPs) Contractor Safety Guidelines posted in the set of documents below. Note that a link to this web page—the single, official PG&E site for GASOPs Contractor Safety Requirements—is included in the Safety Section of every PG&E Construction Contract.

- Table of Contents: GASOPs Contractor Safety Program Requirements (PDF, 119 KB)

- Doc 1 Attachment A: Access Instructions for PG&E Unifier and TIL (PDF, 1.0 MB)

- Doc 2 Attachment B: Site –Specific Safety Plan Submittal Process Guide (PDF, 373 KB)

- Doc 19 Attachment S: Utility Standard: SAFE-1002S Motor Vehicle Safety Standard (PDF, 566 KB)

- Doc 26 TD-4621S: Excavation Safety (PDF, 54 KB)

- Doc 27 TD-4621M: Excavation Safety Manual (PDF, 10.1 MB)

- Doc 28 TD-4441S: Gas Clearances (PDF, 160 KB)

- Doc 29 TD-4441P-11: System Maintenance Clearances for Gas Transmission Facilities (PDF, 180 KB)

- Doc 30 TD-4441p-2 0: Hazardous Energy Control (Lockout and Tagout) for Gas Clearances REV 0a dtd 10-7-15 (PDF, 152 KB)

- Doc 60 Utility Procedure: TD-4412P-05 Excavation Procedures for Damage Prevention (PDF, 460 KB)

- Doc 95 Utility Standard: SAFE-3001S Contractor Safety Standard (PDF, 328 KB)

- Doc 116 TD-4441P-10: System New Clearances for Gas Transmission Facilities (PDF, 185 KB)

- Doc 117 TD-4441P-15: Guidance Document Analysis for Non-Clearance Routine Trans Work (PDF, 109 KB)

- Doc 121 Site Specific Safety Plan (SSSP) Format (DOC, 144 KB)

- Doc 122 Contractor Safety Program Contract Requirements (Based on Utility Standard: SAFE-3001S) (PDF, 342 KB)

- Doc 123 Utility Standard: SAFE-1005S Personal Protective Equipment Standard (PDF, 208 KB)

- Doc 124 Utility Procedure: SAFE-3001P-07 Contractor Safety Oversight Procedure - Gas Operations (PDF, 700.42 KB)

- Doc 125 Attachment C: Contractor Safety Program Risk Matrix (PDF, 722 KB)

- TD-4014S Change Control (Management of Change) (PDF, 167 KB)

- TD-4014P-05 Field Design Change Process for Distribution Lines and Dual-Asset Facilities (PDF, 231 KB)

- TD-4014P-06 Field Design Change Process for Transmission Pipelines and Transmission Station Designs (PDF, 342 KB)

PG&E service area emissions map

Our centralized, searchable map shares the last three years of gas-related emissions data. We collect the data by surveying of our complete gas-pipeline system. The data is tracked and measured against our goal to achieve a service-area-wide decline in year-over-year emissions from pipelines.

How to use the map

From the bar above the map:

- Use the buttons to select the year or 3-year average.

- Select a ZIP Code from the drop-down list or use the search function.

- For an alternative view of the emissions, select the layer box at the top right corner of the map, and select "Methane Emissions Hatch."

Notes:

Bar charts will display emissions data and percentage of mains surveyed.

Surveyed areas vary from year-to-year. Emissions are extrapolated for areas that are not surveyed.

Mcf/yr = 1,000 cubic feet per year (standard unit of measure for natural gas).

Note: Internet Explorer is not supported for this application.

Emissions is the term used to describe the release of gas to atmosphere. Methane emissions quantities from PG&E's pipeline system are not harmful to human health. However, they can have impact on the environment, including global warming. That is why we take an aggressive approach to reducing emissions on our system. Learn more about our commitment to combat climate change.

In 2016, the U.S. Environmental Protection Agency launched a Methane Challenge. PG&E was one of the 41 founding partners. Download our Methane Challenge fact sheet (PDF).

- The development and use of state-of-the-art methane-detecting technologies are key to PG&E’s efforts to reduce overall gas emissions. It also advances our commitment to combat climate change and help the state achieve and surpass its clean energy-goals.

- PG&E has one of the nation’s leading Research and Development teams working to develop, test and pilot new emissions-detection technologies. We were one of the first companies to collaborate with Picarro Inc. to adapt highly sensitive methane-detection technologies onto a mobile vehicle platform.

- We maintain a fleet of 10 vehicles equipped with the Picarro mobile survey technology. This technology is used to identify, measure and prioritize Super Emitters for repair. We also survey the pipeline system on foot for any signs of emissions.

- PG&E piloted new technologies, including RKI Instruments’ open-path laser spectrometer methane sensor. The sensor was originally developed by NASA's Jet Propulsion Laboratory (JPL) to identify menthane on the planet Mars.

- We are evaluating various continuous monitoring and aerial methane detection systems to identify emissions on an accelerated basis.

- PG&E implemented drafting, cross compression, flaring and project bundling, separately and in combination. This reduced the amount of natural gas released into the atmosphere during construction and repair projects. We also added a third stage of compression during cross-compression activities. This decreased the pressure within the isolated pipeline further to reduce emissions.

Natural gas pipeline inspections are conducted on the larger gas transmission pipes twice a year. They’re also done annually for the smaller diameter distribution pipelines within the main business areas of communities. Non-business areas are inspected every three years. Gas-related emissions surveys are conducted to ensure the safe, reliable and affordable delivery of clean natural gas.

All emissions or leaks found on our pipeline system are prioritized and graded according to a national standard. Factors including location, emissions and size are considered as part of this process. The standard is set by the American Gas Association Gas Piping Technology Committee.

Emissions that pose a threat to safety are immediately repaired. Other leaks are prioritized and placed on a repair schedule. In addition to our annualized surveys, we respond within 20 minutes to all calls from customers regarding suspected leaks.

The emissions data we collect is organized on the map (see below) by ZIP code. The map provides a three-year history of PG&E’s service area. The ranking of cumulative emissions is color coded. The map is updated each spring once the annual data is analyzed.

Since 2010, we've made significant enhancements and upgrades to our 50,000+ mile natural gas pipeline system. Our work includes:

- Installing a combined 8,157 SCADA visibility and control points on distribution and transmission lines, which monitor pressure and flow of gas 24-hours a day and feed that data back to the Gas Control Center.

- Reducing the number of open leaks on its system.

- Replacing 1,185 miles of distribution pipeline.

- Replacing 278 miles of transmission pipeline.

- Pressure testing 1,566 miles of transmission pipeline.

- Installing 399 automated valves;

- And, modernizing 1,925 miles of gas transmission line to accommodate inspection tools.

We report our greenhouse gas emissions to the California Air Resources Board and the U.S. Environmental Protection Agency (EPA). On a voluntary basis, we report a more comprehensive emissions inventory to The Climate Registry, a nonprofit organization.

Each year, we also report our greenhouse gas emissions and climate change strategies to the CDP (PDF). CDP is an international not-for-profit organization that requests information on behalf of institutional investors.

Reducing methane emissions is part of our commitment to meet our changing climate. We are helping our State meet its bold clean energy and greenhouse gas reduction goals. We are delivering clean and renewable energy to our customers and strengthening our infrastructure. This helps us reduce our carbon footprint. We are supporting local efforts to make the communities we serve more resilient to climate threats. Learn more in our annual Corporate Responsibility and Sustainability Report.

More on safety

Call before you dig

Call 811 before you dig. Stay safe, stay informed.

Carbon monoxide poisoning

Keep your family safe with early detection.

Excess flow valves

An excess flow valve (EFV) automatically closes and significantly restricts unplanned or excessive natural gas flows if a pipeline is severed by digging. Download EFV information (PDF), and then complete your application in "Your Projects."

Safety Bulletin Natural Gas Odor Fade

Information for personnel involved in the design and construction of new gas piping systems.

©2025 Pacific Gas and Electric Company

©2025 Pacific Gas and Electric Company